3D Open Core

Technical Advantages

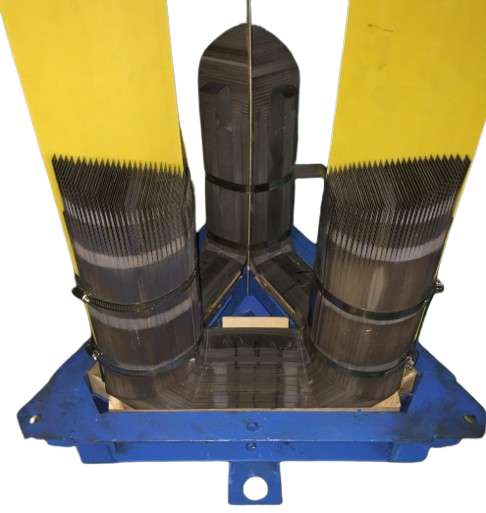

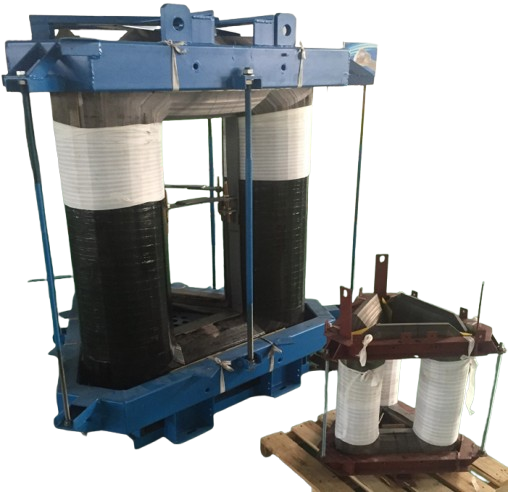

The 3-D open core consists of three single-core frames, each formed by continuously winding trapezoidal steel strips, assembled into a symmetrical 3-D structure. Compared with conventional transformer cores, it offers technical advantages such as:

Balanced three-phase performance: all three legs have identical and minimal magnetic circuit lengths, compared to traditional stacked or wound core.

Cost saving:

The 3D open-type core manufacturing process achieves a material utilization rate of nearly 100% (compared to a 90-95% utilization for stacked core);

With similar core section, window width and height, 3D open core has less yoke to leg ratio. It will normally save 25% of the yoke, saving 5-10% of total steel.

With the same core section area, a circular shape has less perimeter than a rectangular shape. Therefore, 3-D core has less average length per turn, which could save approximately 10-15% of the conductor.

Save 10-15% of total material cost.

Lower NL loss, higher efficiency.

Better short circuit withstanding capabilities, due to circular cross section.

Manufacturing Process

Prepare the 3D core design.

Core and coils are processed separately. Transformer manufacturers can utilize their existing winding machines — no special equipment, additional training, or extra investment is required.

Open the top yoke, assemble the coil and insulation onto the core legs, reassemble the top yoke.

For any special inquiries, please contact us at email: sales@qyualitytransformersolutions.com

Technical Support

Sample is available upon request.

Our engineer can provide design drawings for customer reference.

Our engineer will collaborate with customers to review and optimize their design drawings, ensuring that the designs are compatible with their transformer products.

We offer a variety of silicon steel materials for customer selection.