Low Voltage Distribution Transformers — Dry Type

-

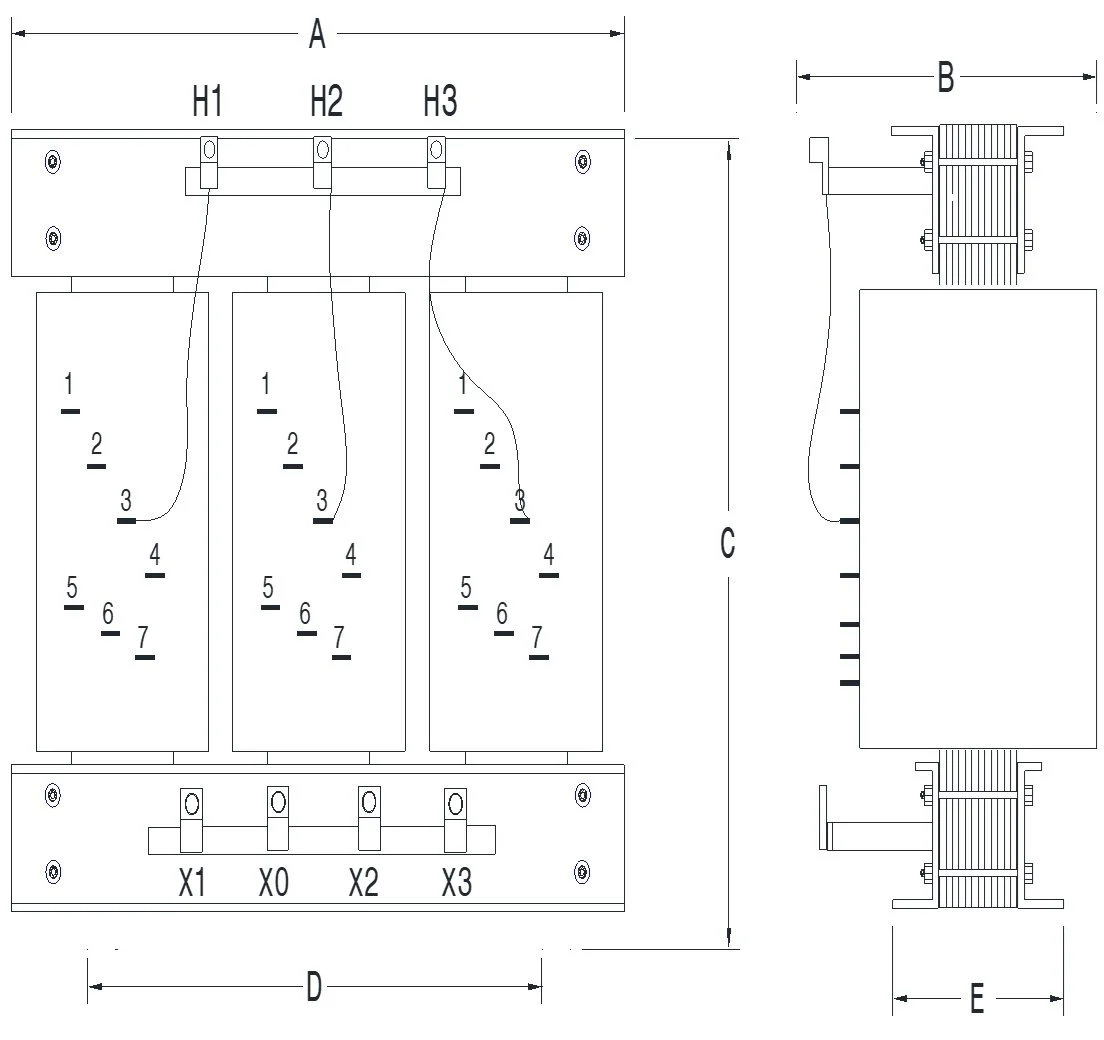

General Purpose Isolation Transformers are primarily used to step down distribution voltages for safe and efficient power distribution within commercial and industrial facilities. We provide customized engineering and design services to meet customers’ specific requirements, such as impedance, K-Factor, enclosure size and etc. Our designs meet efficiency levels (DOE 2016/NRCan 2019 or higher) when required by the customer, and pass all corresponding tests in compliance with CSA and UL standards (CSA C22.2 No47; UL1561; CSA C66.1; CSA C9; IEEEC57.12.91).

Capacity: Single Phase: 3 to 333kVA; Three Phase: 5 to 1,000kVA

Voltage Class: 1.2 kV (CSA), 600 V (UL)

BIL: 10kV

Single Phase Connection: single-dual, single-single, dual-dual, dual-single, multiple-dual

Three Phase Connection: Dyn1, Dyn11, Dd, YNyn, Yyn, Yy, YNd

Winding Material: Copper, Aluminum

Insulation Class: 220⁰C

Temperature Rise: 150 ⁰C, 130 ⁰C, 115 ⁰C, 80 ⁰C

Frequency: 60Hz, 50/60Hz

Cooling: ANN, ANC

Taps: typically +/- 2 x 2.5%, +2/-4 x 2.5%, other taps are available

Impedance: 3.5 - 5% for 25kVA and below, 4 - 6% for 37.5kVA and above, other impedance is available

K-Factor: K1 (Standard), K4, K9, K13, K20, K35

C&C size: customizable to fit any enclosure size.

Sound Level: Per CSA C9 and NEMA ST-20, lower sound level, -1dB,-2dB, -3dB etc available

-

Non-linear loads are becoming increasingly prevalent in modern power distribution systems due to the growing use of electronic devices and power electronics. These non-linear loads produce non-sinusoidal wave shape current on secondary side of a transformer, meaning the current waveform is not directly proportional to the voltage waveform.

The non-sinusoidal currents are comprised of a fundamental current and harmonic currents. As a result, the high frequency harmonic currents will generate extra eddy current losses in winding and stray losses in metal parts, which can lead to transformer overheating. Harmonic currents that are three times the fundamental frequency in a three-phase system will flow through the neutral conductor.

K-Factor transformers are designed to handle the additional eddy current losses in the windings and to ensure that the windings do not exceed their operating temperature rise. The neutral terminal size in a wye connection will be double that of the line terminal size.

For available specifications, please refer to General Purpose Isolation Transformer.

-

General-purpose and K-factor rated transformers have high impedance to harmonic currents, leading to voltage distortion on the secondary and increased losses in connected equipment. While K-factor rated transformers are only designed to withstand these additional losses, Harmonic Mitigating Transformers (HMTs) actively minimize voltage distortion and power losses caused by harmonic currents.

Through phase shifting on the secondary windings, low zero-sequence impedance is created. The low zero-sequence impedance restricts the zero-sequence harmonic currents (3rd, 9th, 15th, etc.) to circulate within the secondary windings, preventing them from entering the primary windings. HMTs with various phase-shifting configurations can mitigate 5th, 7th, and higher-order harmonics at the common bus supplying all the transformers.

For available specifications, please refer to General Purpose Isolation Transformer, for three phase.

Available Connection: DZ, DV

-

Encapsulated (Potted) Transformers are designed for applications where environmental conditions make general-purpose ventilated dry-type transformers unsuitable. In these units, the entire core and coil assembly is fully encapsulated in a silica sand and epoxy resin mixture, forming a solid, protective mass. This encapsulation seals the windings against airborne contaminants, moisture, and other harmful environmental factors. Typical applications include: petrochemical plants, steel mills, pulp & paper facilities, mines, pump houses, and underground locations.

Capacity: Single Phase: 1 to 125kVA; Three Phase: 2 to 150kVA

Voltage Class: 1.2 kV (CSA), 600 V (UL)

BIL: 10kV

Winding Material: Copper, Aluminum

Insulation Class: 200⁰C

Temperature Rise: 130 ⁰C, 115 ⁰C, 80 ⁰C

Frequency: 60Hz, 50/60Hz

Cooling: ANC - Self Cooled

Taps: typically +/- 2 x 2.5%, other taps are available

K-Factor: K1, K4, K9, K13, K20, K35

C&C size: customizable to fit any enclosure size.

Sound Level: Per CSA C9 and NEMA ST-20, lower sound level, -1dB,-2dB, -3dB etc available

-

Autotransformers feature a single winding per phase, part of which is shared between the primary and secondary circuits, providing a compact and economical way to connect equipment to a power supply or different voltage. While they do not provide electrical isolation, they perform the same function as an isolation transformer of the same kVA and voltage rating, typically radiate less noise, and can be used in either step-up or step-down configurations. Autotransformers are exempted from NRCan and DOE efficiency requirements.

Capacity: Single Phase: 3 to 333kVA; Three Phase: 5 to 1,000kVA

Voltage Class: 1.2 kV (CSA), 600 V (UL)

BIL: 10kV

Winding Material: Copper, Aluminum

Insulation Class: 220⁰C

Temperature Rise: 150 ⁰C, 130 ⁰C, 115 ⁰C, 80 ⁰C

Frequency: 60Hz, 50/60Hz

Cooling: ANN, ANC

Taps: typically +/- 2 x 2.5%, other taps are available

Impedance: 4 - 6%, other impedance is available

K-Factor: K1, K4, K9, K13, K20, K35

C&C size: customizable to fit any enclosure size.

Sound Level: Per CSA C9 and NEMA ST-20, lower sound level, -1dB,-2dB, -3dB etc available

-

Designed specifically to supply power to VFDs and provide isolation between the power source and the drive system, such as a motor drive or variable frequency drive. The transformers are designed with a standard K4-factor to keep eddy and stray losses to a minimum. Thermal sensor is embedded in the LV coil and connected to terminal blocks, allowing for remote monitoring and protection. ONLY required for NRCan 2019.

Capacity: 5 to 900kVA

Voltage Class: 1.2 kV (CSA), 600 V (UL)

BIL: 10kV

K-Factor: K4 (standard), K9, K13, K20, K35

Winding Material: Copper, Aluminum

Insulation Class: 220⁰C

Temperature Rise: 150 ⁰C, 130 ⁰C, 115 ⁰C, 80 ⁰C

Frequency: 60Hz, 50/60Hz

Cooling: ANN, ANC

Taps: typically +/- 2 x 2.5%, other taps are available

C&C size: customizable to fit any enclosure size.

Sound Level: Per CSA C9 and NEMA ST-20, lower sound level, -1dB,-2dB, -3dB etc available