Epoxy Resin

General

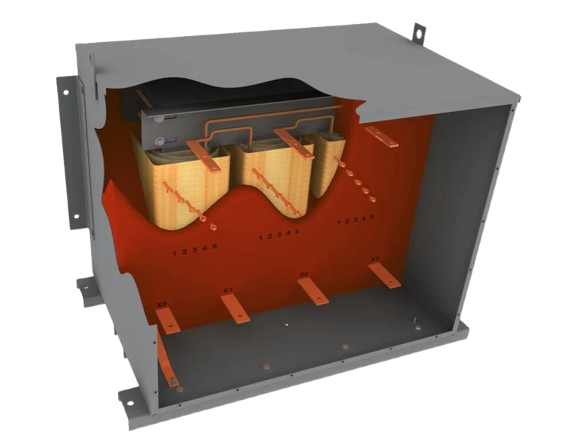

Epoxy resin is a crucial component in dry-type transformers, acting as an insulator and providing mechanical support. Its excellent electrical insulation properties, high thermal stability, and resistance to moisture make it ideal for this application. Additionally, epoxy resin is non-flammable and self-extinguishing, enhancing the safety of dry-type transformers.

Application

Epoxy Resin are commonly used in Encapsulated (Potted) Transformers in North America for applications where environmental conditions make general-purpose ventilated dry-type transformers unsuitable. In these units, the entire core and coil assembly is fully encapsulated in a silica sand and polyurethane (or epoxy) mixture, forming a solid, protective mass. This encapsulation seals the windings against airborne contaminants, moisture, and other harmful environmental factors.

Typical applications include:

Corrosive environments – such as petrochemical plants, steel mills, and pulp & paper facilities.

Damp or wet conditions – including mines, pump houses, underground locations, or rooftop service areas.

Dust-laden or particle-heavy processes – industries with high levels of airborne dust, conductive particles, or other pollutants.

Product Specification

This product is a two-component epoxy resin system. It remains in liquid form at room temperature and is primarily designed for encapsulated (potted) transformers due to its good heat resistance, excellent mechanical and electrical properties..

Base Material (Part A): Epoxy Resin

Curing Agent (Part B): Hardener

The mixing ratio (by weight) for the above products is 100:80

Curing Conditions: 80 °C for 6 hours, followed by 140 °C for 6 hours.

Insulation Level: H (or F)

Item Part A Part B

Appearance Red viscous liquid Gray-white viscous liquid

Viscosity (25 °C) (mPa·s) 20,000 – 50,000 2,000 – 10,000

For any special inquiries, please contact us at email: sales@qyualitytransformersolutions.com