Vapor Phase Drying Plant (VPD)

Mobile & Stationary

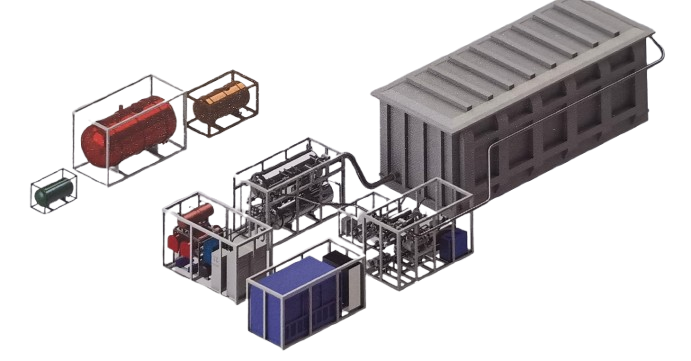

Mobile VPD

The mobile vapor-phase drying equipment (MVPD) realizes the vision of “bringing the factory to the power station,” enabling factory-level inspection and maintenance of transformers directly at the site.

MVPD Highlights

No need to return faulty transformers to the factory – on-site condition monitoring and vapor-phase drying.

Perfect for field-assembly power transformers drying and testing.

Superior drying performance – reduces moisture from solid insulation to <0.5%, greatly extending transformer service life. This level of dryness cannot be achieved by existing on-site drying processes such as Mobile LFH, hot-oil spray under vacuum, or hot-oil circulation under vacuum.

Modular structure – compact design with no excess height or width, ensuring easy transportation.

Reduced downtime – significantly shortens transformer outage periods by enabling on-site factory-level drying.

Cost savings – eliminates high transportation expenses associated with sending transformers back to the factory.

Lower risk – removes the risks of damage during transport.

Faster process – treatment time is considerably shorter compared with any other on-site drying technologies, thus a much faster on-site inspection.

Advantages of MVPD over Stationary VPD (with respect to site conditions)

Quick on-site setup – Before the drying process, only a few flexible metal pipes (corrugated tubes) need to be connected between the MVPD modules and the transformer’s oil tank, along with the supply power and cooling water pipes.

Shorter drying time – It only takes 3-4 days to dry a 110kV transformer;

4-5 days for 220kV transformer;

8 days for a 500kV/750MVA transformer;

9 days for a 500kV/1000MVA transformer.

Double-evaporator design for efficient drying process – For transformers requiring multiple distillation cycles (often more than ten), the double-evaporator design plays a crucial role in enhancing drying performance and accelerating the process..

Equivalent drying process and performance to stationary VPD – the winding temperatures can reach up to 128°C, core temperatures up to 120°C, ultimate vacuum below 10 Pa, and the moisture content of the insulation sample reduced to <0.5%.

Other Transformer Drying Plants

Stationary VPD Plant

Pressure Alternating Drying Plant

Transformer Oil System

Technical Support

Our engineer can provide drawings and specifications for customer reference.

Our engineer will collaborate with customers to review which type of VPD plant suits their transformer products.

Company Info

The company has 30+ years of experience in the application, operation and maintenance, R&D, and manufacturing of VPD equipment, integrating Swiss and German technologies with its own innovations.

Through independent design and manufacturing, the company has supplied dozens of stationary VPD plants and 7 sets of mobile VPD plant to many top transformer manufacturers and transmission & distribution companies. The largest transformers processed with the MVPD plants include a single-phase 1000 kV/1000 MVA unit, a three-phase 750 kV/1230 MVA unit, and a ±800 kV HVDC. All of these products have passed the required tests and have been successfully put into grid operation.

For any special inquiries, please contact us at email: sales@qyualitytransformersolutions.com