Winding Machines

Company Info

The company specializes in the production of CNC low-voltage foil winding machine, high-voltage foil winding machine, transformer coil winding machines, horizontal and vertical winding machines. With 15 years of experience in transformer equipment design and production, the company has established cooperative relationships with leading enterprises worldwide.

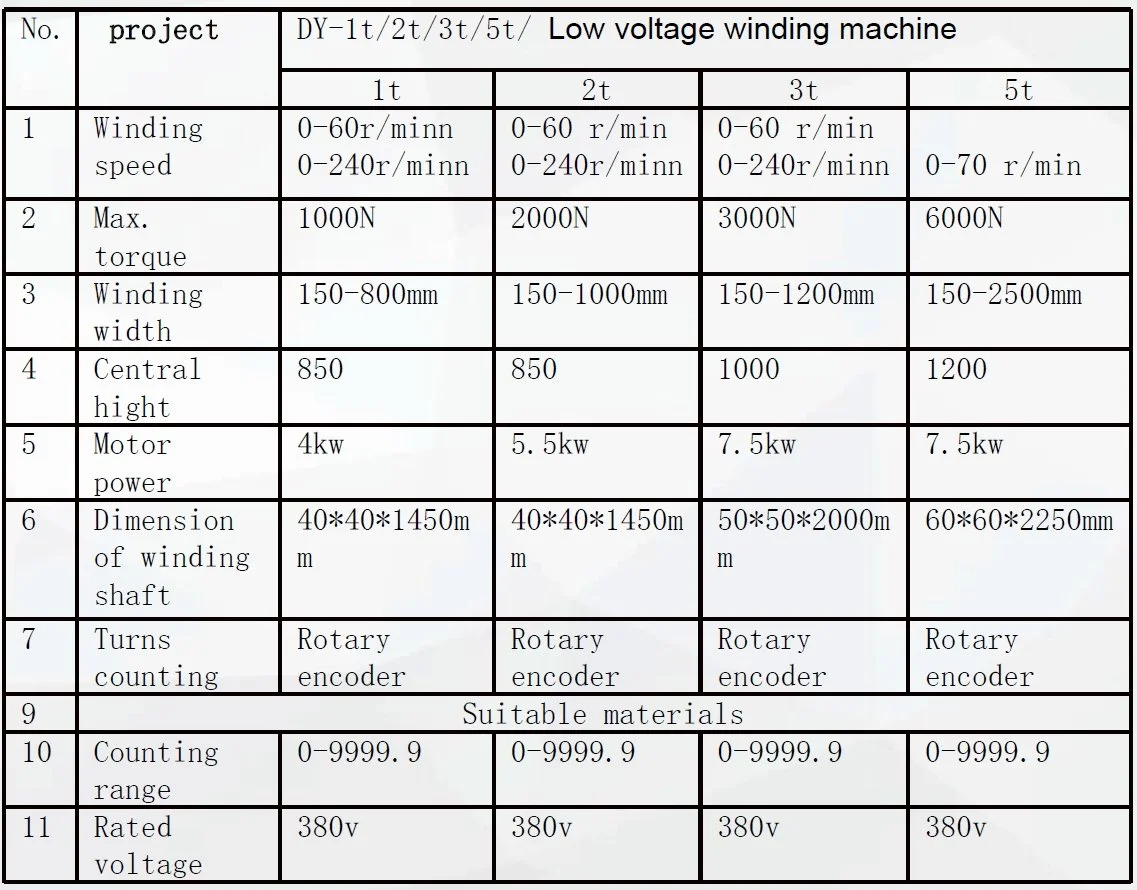

High & Low Voltage Winding Machine

This machine is used for winding high voltage and low voltage coils of transformers. It adopts motor reducer to drive gear, stable and reliable stop, winding, automatic counting, power off memory function, encoder counting, foot switch into the background control, inverter imported encoder control.

For any special inquiries, please contact us at email: sales@qyualitytransformersolutions.com

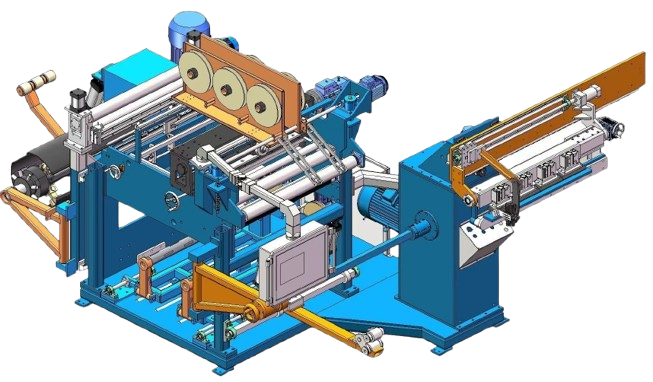

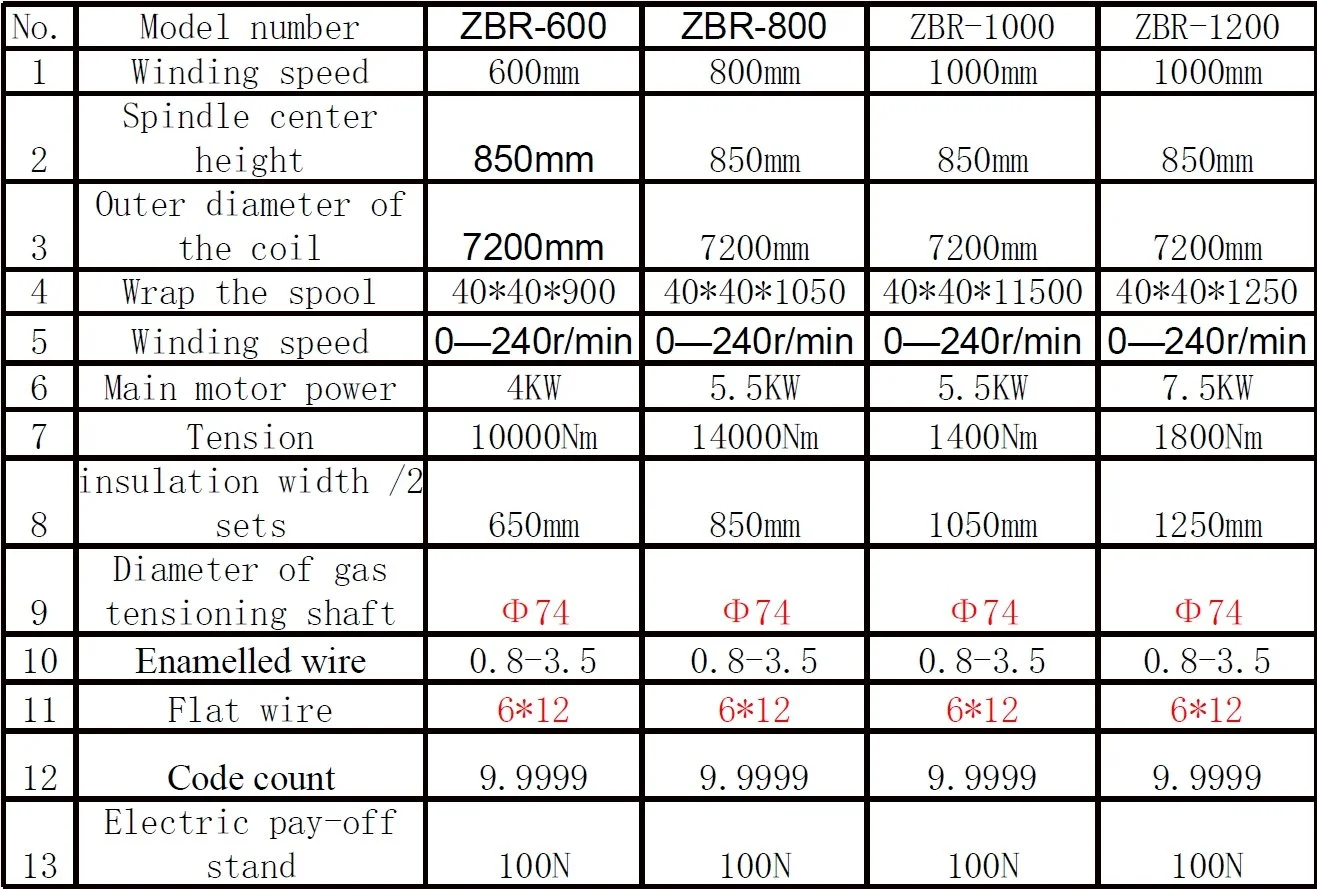

Automatic Winding Machine

Automatic winding machine is used for all kinds of small and medium-sized distribution transformers of round or rectangular coil, suitable for high voltage coil manufacturing. Wire speed 240 RPM, main motor power 5.5KW, coil diameter up to 720mm.

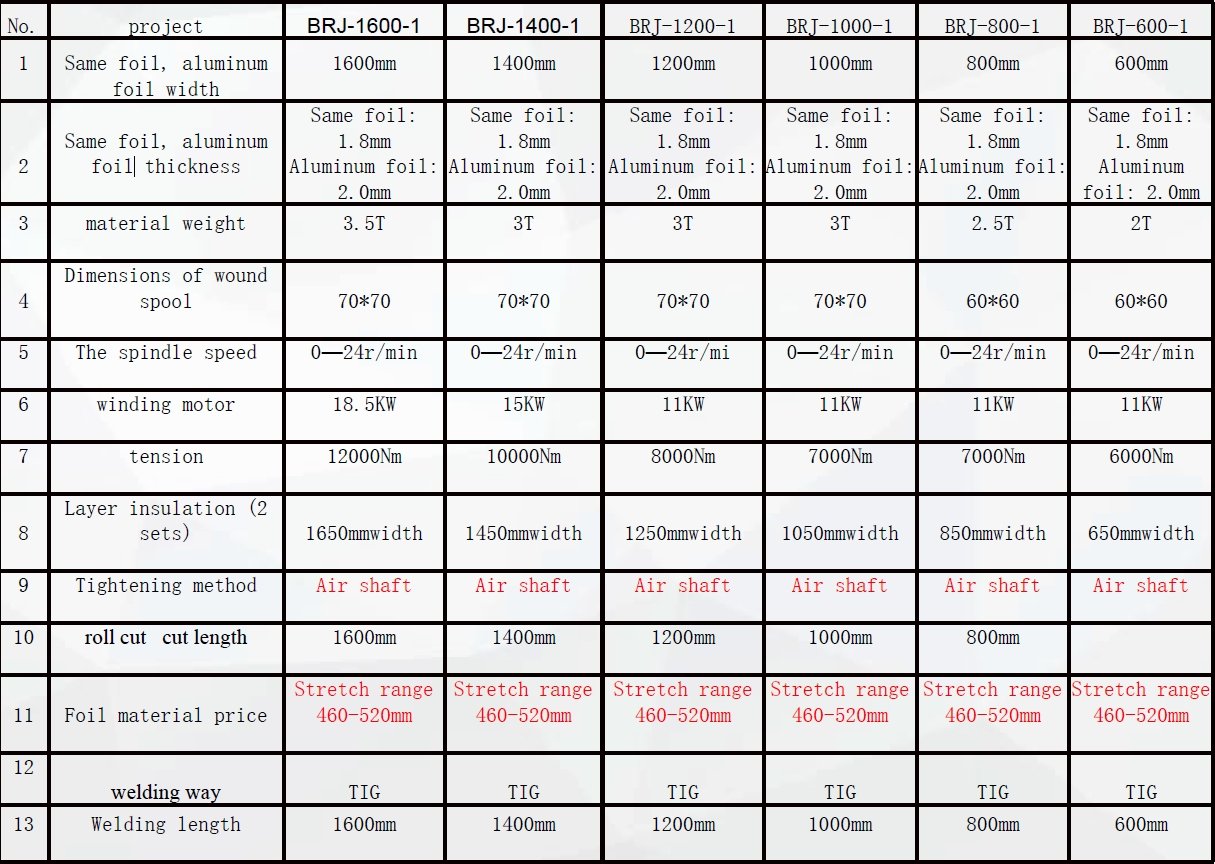

CNC Single Foil Winding Machine

The main parts of CNC foil winding machine consist of copper foil/aluminum foil placing device, layer insulation device, winding device, deviation correction device, automatic welding device and other major parts. The automatic correction device, equipped with a high-precision correction sensor system, completely solves the correction accuracy problem in copper foil and aluminum foil winding machines. The system adopts electric tension control for copper and aluminum belts.

For any special inquiries, please contact us at 647.667.1004 or email sales@qyualitytransformersolutions.com